- Decrease font

- Increase font

-

Click here to bookmark this page

My Bookmarks

×Customize your Bookmarks:

- Type the name of the page the way you would like it to appear in "My Bookmarks";

- Click in the "Add as My Bookmarks" button.

To choose your favorite sessions, please click here.

- Send a friend

Sustainable performance:

a crucial basis of support

Our business

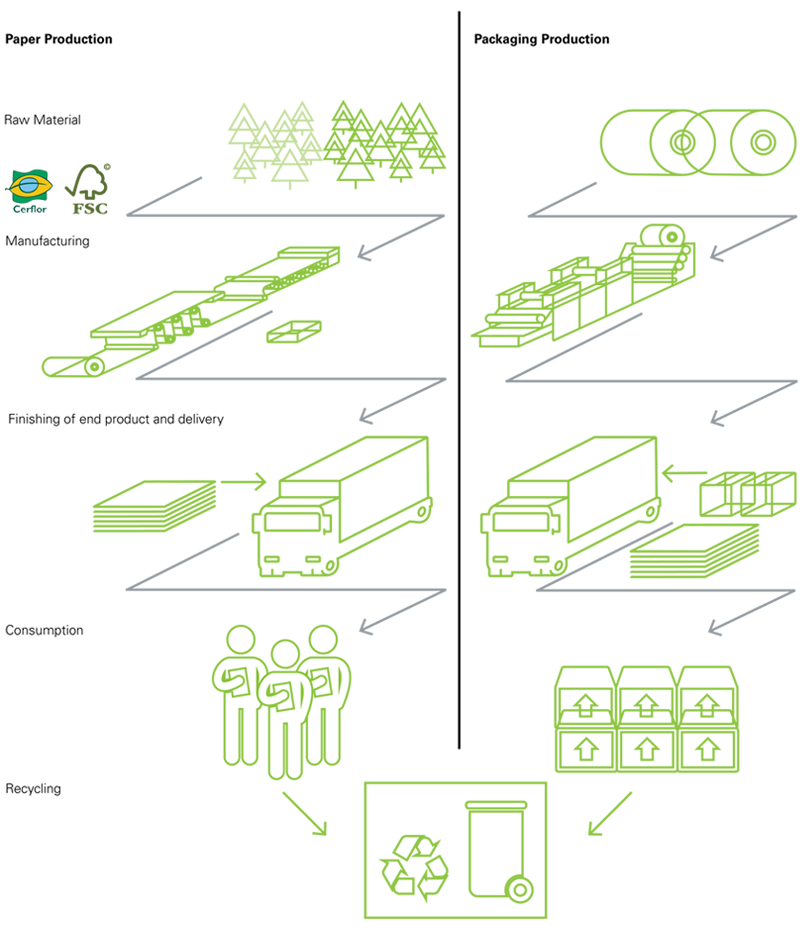

Paper from eucalyptus plantations

All the company's paper production is made from planted eucalyptus forests, cultivated in a sustainable manner

It is essential to note that all of the Company’s paper is made from planted eucalyptus forests that are sustainably cultivated. This means that not a single tree from native forests has been felled in order to produce paper. IP also has a biomass boiler in which eucalyptus is burned to generate renewable energy. According to BRACELPA (the pulp and paper industry association), for every 100 hectares planted, the sector preserves 170 hectares. In other words, the industry preserves around three million hectares of forests for conservation, recovery and biodiversity studies. Apart from the environmental aspects, the forestry partnering programs benefit more than 20,000 small and mid-sized farms. In addition, the industry’s planted forests create 160,000 direct and 600,000 indirect jobs.

1) Raw material:

The fact that paper comes from a renewable source–wood–is a point in its favor. This is a fast-renewing raw material, as it takes an average of seven years for eucalyptus to reach the ideal felling stage, and it does not take long to decompose.

2) Certified, cultivated and renewable forests:

It is important to note that in Brazil, 100% of pulp and paper is produced from planted forests, according to BRACELPA . Although planted forests occupy less than 1% of the country’s land, they contribute to compliance with a series of economic, social and environmental principles, having been certified by the Forest Stewardship Council (FSC) and the Brazilian Forestry Certification Program (PEFC/Cerflor).

IP Latin America's forest holdings:

- 102,000 hectares in the states of São Paulo and Minas Gerais;

- 72,000 hectares allocated to eucalyptus reforestation;

- 26,000 hectares of native forest under conservation.

3) Pulp and paper manufacture:

The entire production process is planned with the aim of causing the least possible impact on the environment and the plants’ surrounding communities. One example of this concern is the growing use of biomass from the Company’s own forests as an energy source for generating steam in the Brazilian factories. For example, as of 2013, 90% of the energy used by International Paper's Integrated Manufacturing System has been generated by biomass from renewable sources.

4) Recycling:

According to BRACELPA’s1 2009 figures, Brazil recovers around 46% of the paper it produces. Since pulp quality is adversely affected during recycling, this solution is normally applied to items such as cardboard, toilet paper, buff paper and newsprint, which do not require the same quality of texture as printing and writing paper. The types of materials that can be recycled include books, newspapers, magazines, other printed matter, envelopes and boxes that do not contain plastic.

¹As of April 2014, BRACELPA and the Brazilian Forest Association (ABRAF) became part of a single entity called the Brazilian Tree Industry (IBÁ), in which the Company participates.

The chart below illustrates the process.