- Decrease font

- Increase font

-

Click here to bookmark this page

My Bookmarks

×Customize your Bookmarks:

- Type the name of the page the way you would like it to appear in "My Bookmarks";

- Click in the "Add as My Bookmarks" button.

To choose your favorite sessions, please click here.

- Send a friend

Sustainable performance:

a crucial basis of support

Environmental responsibility

Energy

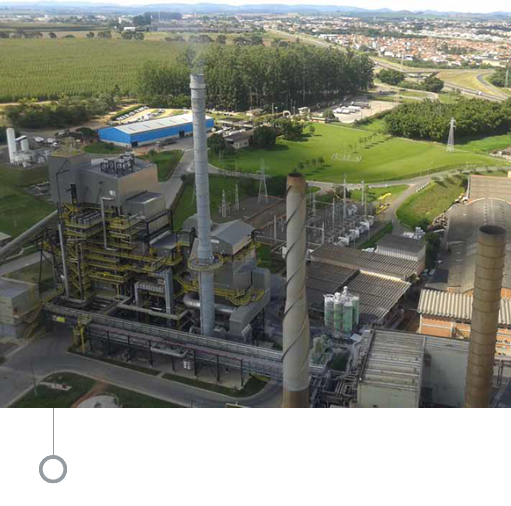

Mogi Guaçu Biomass boiler

Recent investment which enabled us to increase the mills’s energy self-sufficiency.

Energy consumption has a direct effect on operating costs and can increase exposure to fluctuations in energy supply and prices. Currently, energy represents one of International Paper highest industrial costs. Consequently, the Company is continuously seeking to improve its energy efficiency.

Energy efficiency projects are being developed though investments in innovation and the adoption of the Lean Six Sigma methodology, which focuses on generating efficient results through three pillars: staff training; assertive project development; and the structuring of systems designed to produce sustainable results.

Each IP unit monitors its monthly energy consumption through four indicators, thereby facilitating comparisons among the units: total energy consumed over volume of product produced, purchased energy over volume of product produced, energy cost over volume of product produced, and energy cost over energy consumed. Based on the results, the Company establishes targets, and draws up action and mitigation plans.

One of the initiatives in this area is the replacement of high energy consumption equipment with more energy-efficient versions. In order to reduce energy consumption, IP has invested in the acquisition of more efficient machinery and installed a biomass boiler in the Mogi Guaçu unit.

Despite the issue’s importance, IP does not have a specific energy efficiency policy as yet, although it is included in the Organization’s global sustainability targets.

At Orsa IP, the replacement of energy matrices is part of its strategic plan, including a project to install a biomass boiler to replace the oil and gas boilers. There are also short-term measures to increase energy efficiency.

Energy intensity

[G4-EN5]

| Year | Production Unit | Energy Intensity (KWh/t) |

| 2011 | ||

| Mogi Guaçu | 13.07 | |

| Luiz Antônio | 3.13 | |

| Três Lagoas | 4.37 | |

| 2012 | ||

| Mogi Guaçu | 12.87 | |

| Luiz Antônio | 3,05 | |

| Três Lagoas | 4.27 | |

| 2013 | ||

| Mogi Guaçu | 6.13 | |

| Luiz Antônio | 2.92 | |

| Três Lagoas | 4.18 |

Reduction in energy consumption

[G4-EN6]

In addition to having a clean energy matrix, International Paper develops initiatives that help reduce energy consumption. Among the initiatives developed in 2013, the following are particularly worth noting:

| Initiative | Total energy saved (GJ/year) |

| 5 ton/hour (t/h) reduction in steam consumption by the Luiz Antônio papermaking machine | 109,746 |

| 1,122 t reduction in oil consumption by the quicklime furnace in the Luiz Antônio mill | 44,555 |

| 8.5 t/h reduction in steam consumption by the Mogi Guaçu mill | 186,568 |

Scope: Orsa IP

| Initiative | Total energy saved |

| The Manaus plant replaced high-energy-consumption air conditioning equipment, which used to result in power outages during peak periods. | 354,600 KWh |

| Maintenance was performed on the Rio Verde mill ‘s capacitor system. | 2,371.36 KWh |